ECY Series Refrigeration Motor

Delivering Energy Efficient Air to Your Refrigerated Application

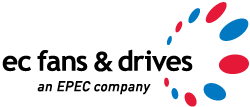

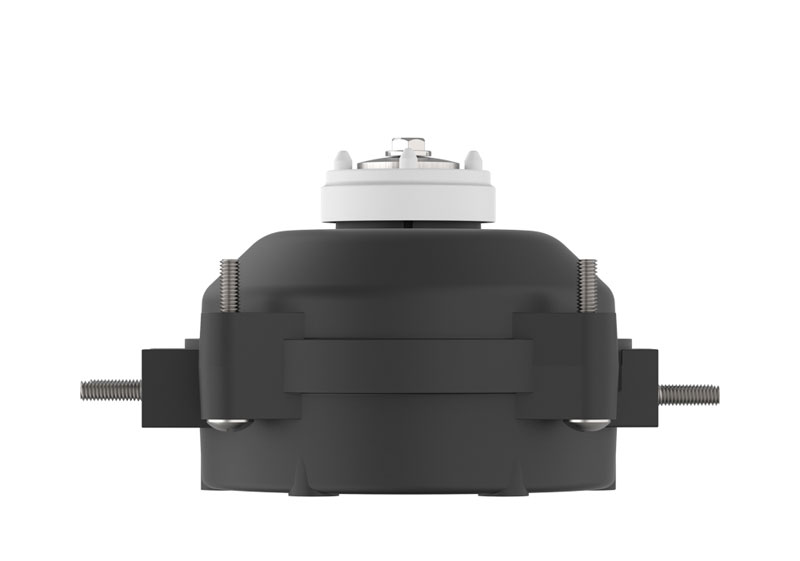

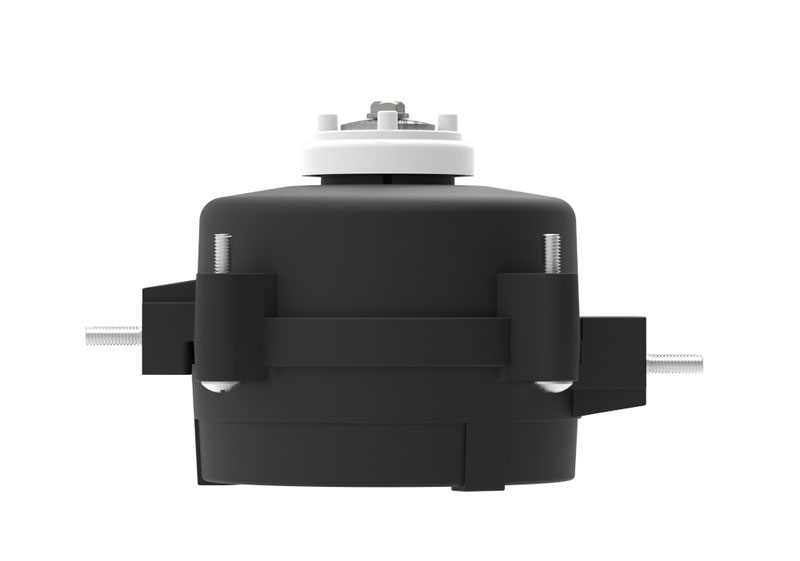

The ECY Series motor platform is an electronically commutated (EC) motor designed for condenser and evaporator applications in commercial refrigerated cases and bottle coolers. It has been designed to allow direct replacement with existing shaded pole motors, therefore allowing drop-in replacement into existing inefficient refrigeration systems. Our team of engineers works with our customers to deliver fan/motor concepts with efficiency levels up to 70%, therefore consuming only one-third of the power of a comparable shaded-pole or unit-bearing motor.

It has been designed to meet the demanding requirements of refrigerated bottle coolers, freezers, and commercial food cabinets that have long operating times, and it's the motor of choice by numerous leading brand refrigeration manufacturers.

Overall ECY Motor Features and Benefits

All the below described features and benefits can be applied to any of the ECY platform models. Over 90% of what we sell to our customers around the globe is customized to meet their specific application needs.

It can be supplied with "reverse on start," which allows the motor to run in reverse for a pre-programmed time on starting. This feature enables a more consistent and higher cooling capacity as it blows any particles of dust out of the condenser.

It also can be supplied with "reverse on demand," which allows the customer to define the duration of the reverse function. This is useful as it could allow the evaporator fan once in defrost mode to blow any particles of dust out from the condenser.

This energy-efficient motor can be supplied in a plastic housing material that satisfies the requirements of the U.S. Food and Drug Administration (FDA) therefore complying with requirements to be used in areas involving incidental contact with foodstuffs. An example of this would be seen in supermarkets with vegetable open-reach display cases.

The ECY Series motor can be supplied with fan rings and axial fan blades (∅154mm ~ ∅254mm) completely assembled. These can be steel, aluminum, or plastic, and we can also add protective cages along with other custom brackets or finger guards per customer request.

It can be supplied to the customer's preferred length and is complete with connectors and molded plugs already assembled for quick connection to the final application.

This motor can be supplied with imperial or metric fastenings, with either the European standard drive plate (drive pips ∅3.5mm) or the USA standard drive plate (drive pips ∅4.2mm).

ECY Series Motor Overview

| ECY-15 Motor | ECY-30 Motor | ECY-45 Motor | |

|---|---|---|---|

|

|

|

|

| Input Voltage | 120-230 VAC | 120-230VAC | 120-230VAC |

| Frequency | 50/60Hz | 50/60Hz | 50/60Hz |

| Input Power | 15 Watt | 30 Watt | 45 Watt |

| Output Power | 8 Watt | 21 Watt | 31 Watt |

| Efficiency | 50% | 70% | 70% |

| Rotational Speed | 500-2100 rpm | 500-2500 rpm | 500-2500 rpm |

| Number of Speeds | 1 or 2 Speed | 1, 2, or 3 Speed | 1, 2, or 3 Speed |

| Bearing System | Ball Bearing | Ball Bearing | Ball Bearing |

| Shaft Diamater | 6mm | 8mm | 8mm |

| Insulation Class | Class B (130c) | Class B (130c) | Class B (130c) |

| Protection | Electronic Thermal | Electronic Thermal | Electronic Thermal |

| IP Rating | IP65 | IP65 | IP65 |

| Temperature Range | -40°C to +50°C | -40°C to +50°C | -40°C to +50°C |

| Life Expectancy | 30,000 Hrs @ 40c | 40,000 Hrs @ 40C | 40,000 Hrs @ 40C |

Hydro-Carbon Friendly

As propane is becoming increasingly popular as an ecological alternative to the traditional refrigerant, we must be aware that when a propane refrigerant system malfunctions, it is possible that the non-toxic hydrocarbons can form readily explosive mixtures with air.

Our ECY motor (230VAC) has been tested by third-party approval and satisfies the requirements of the European standard EN 60335-2-89 (household appliance standard - particular requirements for commercial refrigerating appliances) and ATEX approval to EN IEC 60079, which gives the customer confidence that our products can safely be used in flammable refrigerant systems.

Inventory Management

Historically, the fractional horsepower EC motor business has been plagued by long lead times due to the fact that these motors require a complex printed circuit board (PCB) assembly which is used to control the power output that provides its energy efficiency. Because our parent company, Epec Engineered Technologies, has been in the electronics business for more than 70 years, we understand how these supply chains work and have always been ahead of the curve to make sure that our fan and motor customers never see a supply disruption.

To do this, we offer many customized inventory management programs to ensure that you have product always dedicated to you in our inventory.

These inventory management programs can include:

- Kanban

- Consignment

- JIT Programs

- Blanket Orders

- Customer Fulfillment

- Bonded Warehousing

- Kitting

- Safety Stock

- Other Flexible Solutions

Product Compliance