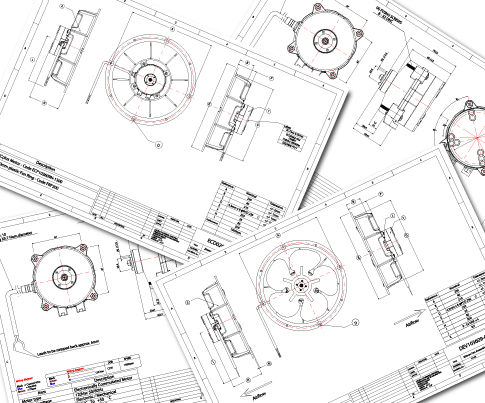

Design Services

EC Fans & Drives provides complete engineering and design services from concept through to production in a quick and efficient time frame. Many people assume they just have to buy a motor and then do any customizations or add features to it themselves. With EC Fans & Drives, this is not true as we can customize every product that we have so that customers can install the product right out of the box. We want you to buy what you want not just what we sell. We can cost-effectively adjust to any application, including designing and providing:

- Custom Housings

- Attachment Rings

- Plastic or Steel

- USA, European, or Combined

- Blades/Impellors - Steel or Plastic (hundreds of different pitch angles available)

- Lead Length and Connector Fittings

- Brass Inserts

- Finger Guards

- Reverse at Start

- Pre-Set Speeds

- ATEX Certifications

- IP Ratings

- Custom Attachment Brackets - Steel or Plastic

- Metric or English dimensioning

- And many others

Our engineers have more than 30 years of experience and knowledge in electric motor and fan design, and we have the ability to think outside the box and create innovative designs and solid manufacturing solutions for our customers' applications. Using our custom capabilities, we can not only reduce labor costs for our customers, but we can change the air flow, minimize the profile height/depth, and even create designs that help the operation of the equipment by reducing the effects of ice buildup and more. Our investment in 3D laser scanning and SLS prototyping facilities assist in design and reverse engineering of your current products if necessary.

Using our motor and fan design center in the United Kingdom, our engineers can design an EC solution with the aid of latest AMCA-approved airflow chambers and Magtrol motor testing equipment. It is estimated by ASHRAE that almost half (45 percent) of global electricity is used by electric motors. Electric motors play a vital role that it pays huge dividends to design and develop electric motors with world class efficiently coupled with first-rate manufacturing process, and this will allow all of our products to pass any customers quality reliability program.

Continuous reliability product testing is monitored at both our United Kingdom and our North American engineering support center in New Bedford, Mass., as well as at all our manufacturing locations. Unlike its shaded pole motor predecessor, EC motors are more than just windings and magnets. EC motors are a very sophisticated electronic piece of equipment that requires a whole different set of skills than just the traditional motor manufacturing experience. Because our parent company, Epec Engineered Technologies, has more than 70 years' experience in the electronics manufacturing business, we are uniquely qualified to ensure that our products will mee the most stringent reliability standards.

Our engineering team prides itself in working closely with customers and meeting expectations within agreed timelines and generating detailed material specifications, product renderings, and prototypes. Starting with SLS samples, we can work with customers to ensure that the design is exactly what they require before we tool up any required customizations to meet their requirements.

Being a good partner means more than just sending you an off-the-shelf motor and letting your customer figure it out on their own. It's about listening to customers, understanding the application, and truly putting resources towards developing the best solution.