Plastic Versus Metal Fan Blades for HVAC and Commercial Refrigeration

When it comes to heating, ventilation, and cooling systems (HVAC), as well as commercial refrigeration applications, the most important feature of these systems is the fan blades (Figure 1). Yet what customers seldom realize is the number of fans that are inside these applications.

For a general HVAC system, there are three types of fans located in the system: an axial fan, a centrifugal fan, and a backward inclined fan. So, when requiring replacement fan blades or designing fan blades, the customer will need to select the right type of fan blade system. Then they will need to consider the materials that they want for the fan blades. The most common material for commercial fan blades is metal (aluminum or steel) or plastic (polypropylene). Yet some companies are also producing fans using nylon textile and fiberglass-reinforced polyester.

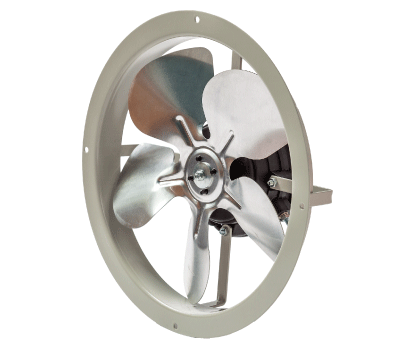

Figure 1: Example of commercial refrigeration using EC fan and motor technology

Fan Types Overview

In many cases, commercial fans are not interchangeable due to the amount of static pressures and air flow that is required. An axial fan cannot be used in place of a centrifugal fan due to the different static pressures (resistance to air flow). While there are numerous fan types out there, such as industrial blowers, impeller fans and exhausters, these fans usually fall into the following three categories of fans:

Centrifugal Fans: Centrifugal fans have a "water wheel" shape and are used in air-handling units. These fans produce a higher pressure than axial fans. They will also produce more noise due to the higher pressures. They have a higher cost than axial fans while providing a higher level of performance.

Axial Fans: Axial fans are the simplest and most cost-effective fans available. The blades are in a propeller shape as they are placed on a rotating axial. A customer should use axial fans for low airflow and low static pressure applications. These fans are commonly found on cooling tower systems and outdoor commercial air conditioning condensers.

Backward-Inclined Fans have an unusual curved blade and are commonly used in applications that have variable pressures and with high airflow. These fans may be found in process cooling systems and HVAC energy-recovery ventilation systems.

Fan Blade Material Comparison

Most commercial and industrial fan blades for HVAC and refrigeration purposes will be made out of either aluminum, metal, or plastic. Replacement fan blades can be purchased separately when the old fan blades become pitted or worn. Customers may also seek to replace the fan blades when the motors of the fans are replaced.

Aluminum, metal, and plastic fans have many similar characteristics. The materials are lightweight, although the weight will be increased based on the size of the blades needed for the application, so, customers may find the types of materials available for specific fans, such as axial fans.

To determine the type of fan material to use, a customer needs to evaluate the static pressures needed and the type of environment that the fan blades will be working in. While these fans will be located in HVAC and commercial refrigeration systems that may offer some protection, the air that is forced through it may contain higher levels of corrosive elements that will impact the blade's performance or increase the wear-and-tear of the fan blades. There may also be more moisture, ice, or even saltwater present. Another factor to take into consideration involve the environmental temperatures, as there may be extreme hot or cold workplaces or outdoor conditions that will impact the fan blades.

Aluminum and Metal Fan Properties

The fan propeller can come in a diameter ranges of 2 inches up to 48 inches, as aluminum/metal blades are often preferred for larger fan systems (Figure 2). The number of fan blades can vary, as there may be as few as 3 blades and as many as 10 blades depending on the type of fan system that is used.

Metal fan blades can be painted or come with a galvalume finish, which is a coating of zinc, aluminum, and silicon for aesthetic purposes. It also adds additional protection to the metal's surface. They are suitable for environments that undergo extreme temperatures. Keep in mind that painted metal may begin to chip and peel away from the blades from wear-and tear, allowing more corrosion to get to the bare metal underneath.

Due to the metal materials, these fan blades can be used for high static pressure fan systems. While the painted metal or galvalume coating offers more corrosion resistance, the fan blades can still be susceptible to rust, chemicals, and other corrosive materials. Also, keep in mind that metal fan blades moving within metal housings at higher speeds can create more noise during operation due to the metal vibrations.

Figure 2: Example of a Fan Pack with aluminium fan blades and steel fan ring

Pros of Metal Fan Blades

- Appropriate for larger fan sizes

- Can handle variable and higher static pressures and air flow

- Can be used in extreme temperatures

Cons of Metal Fan Blades

- Can create loud noise due to vibration

- Susceptible to balancing problems if not handled correctly

- Susceptible to corrosion

Plastic Fan Properties

Plastic fans are made from polypropylene as well as composite plastic resins or polymers. Typical plastic propeller diameter sizes can range from as low as 2 1/2 inches to 8 inches as fans can have 4 blades up to 6 blades (Figure 3). Plastic fan blades are suitable for low static pressure applications.

The plastic for fan blades may be colored for aesthetic reasons or to provide additives such as enhanced UV protection or corrosion resistance. Since the color is impregnated throughout the material, there is less fading or wear to it. Keep in mind that the larger the fan blade, the more additives that must be introduced into the material to stiffen it for variable static pressure applications.

Pros of Plastic Fan Blades

- Corrosion resistance

- Blades designed to give optimum airflow characteristics

- Lightweight and quiet

- Prolongs the life of motors and bearings

Figure 3: Example of a Fan Pack with plastic fan blades and plastic fan ring

Cons of Plastic Fan Blades

- Reserved for smaller fan blade diameters

- Not suitable for higher static pressures

- Not suitable for extreme temperature environments

Summary

When selecting fan materials for standard HVAC systems and commercial refrigeration systems that will be placed into customized products, always look over the manufacturer specifications in regard to the type of fan blades that can be used. This strategy will ensure that the fan blade will provide the maximum operating power and air flow required for the application.

For customers who will be building the entire fan system from the custom design phase, turn to an electronics and electrical design and manufacturing company with years of experience. We help customers decide on the right materials based on the applications so that we can meet their time-to-market deadlines.