EFP Fan Pack

Axial Fan Air Flow Analysis

ECFD EFP200 vs. EBM W1G200 - Air Flow Analysis

The EFP series axial fan is a fully integrated fan pack assembly that has been aerodynamically designed to deliver high-efficiency flow rates at static operating point 50 pascal (0.20 in-H2O) and below. Our goal with developing this assembly was to provide the most reliable and longest-lasting EC refrigeration motor at a competitive price. Part of the ongoing challenges with creating energy-efficient refrigeration models has always been the cost, so we set out to make it easier for our customers to save energy.

Our product was intentionally designed so that the fan ring and fan blade are produced in high-quality engineered plastics. The EFP axial fan has been designed to withstand the most demanding refrigeration systems and offer superior energy saving when compared with competitor branded products. Specific airflow graphs are available from our AMCA-approved airflow chambers located at our manufacturing facility and development lab in Wales, U.K., illustrate flow, pressure, speed, and input power allowing our customers to understand how the EFP axial fan will perform in any application.

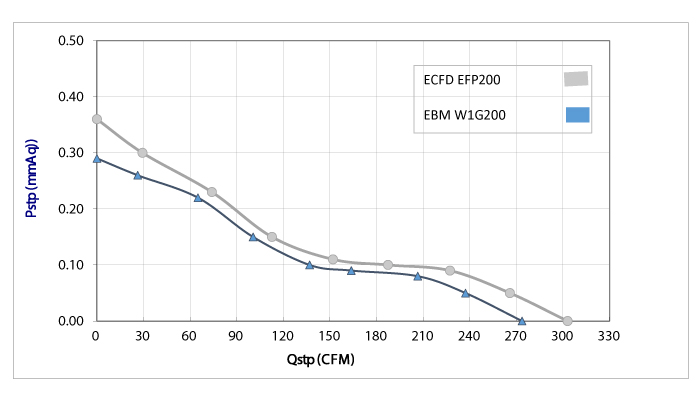

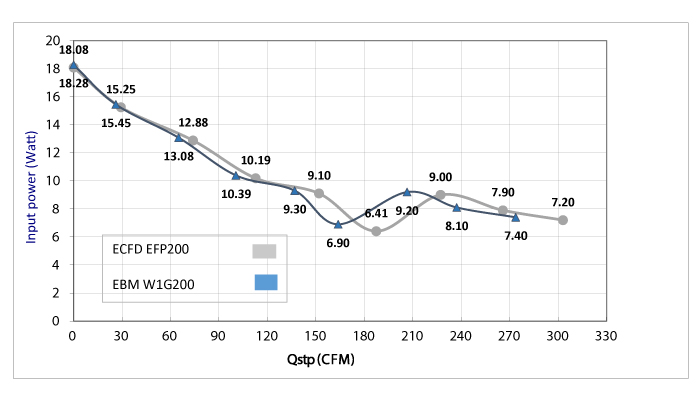

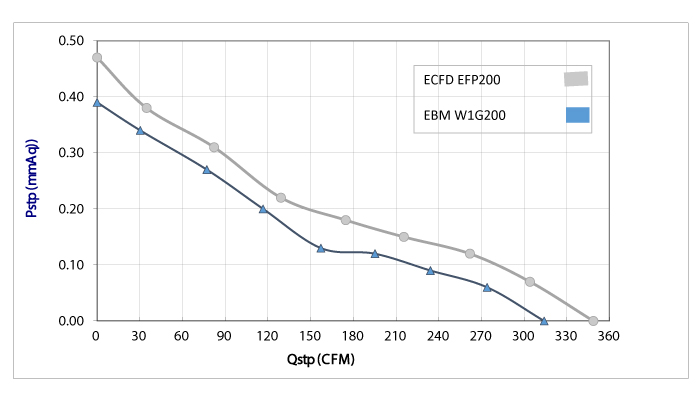

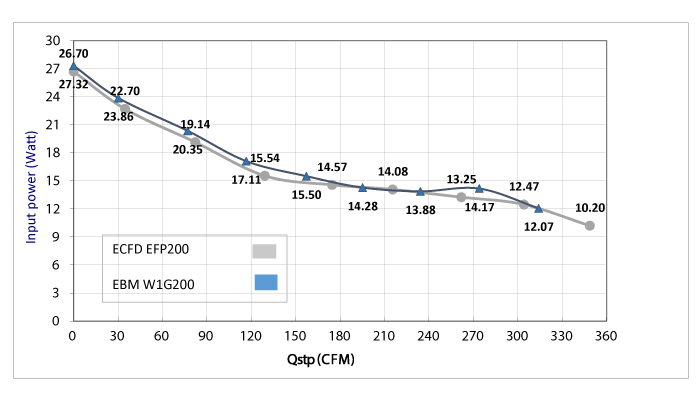

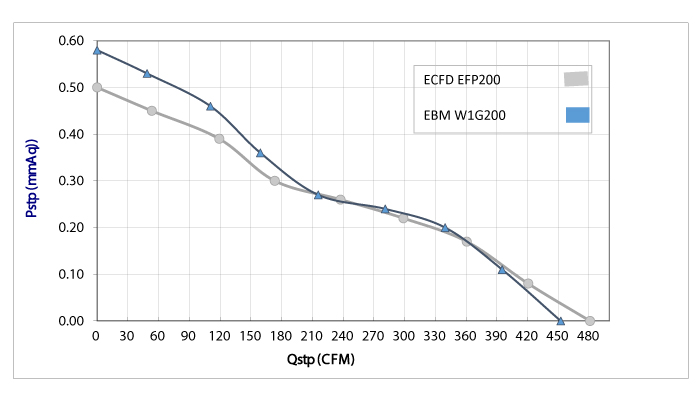

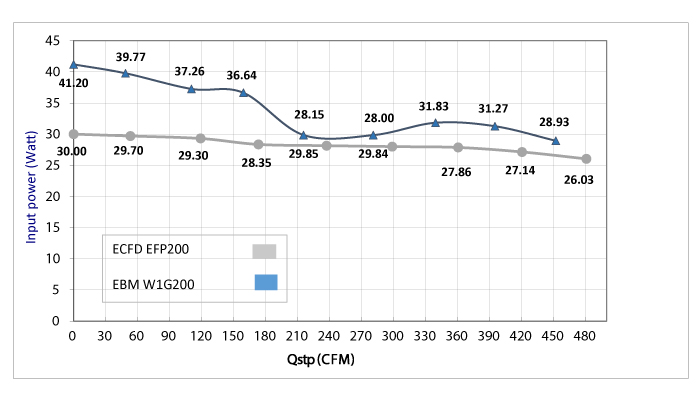

Industry veterans know that ebm-pabst is the world leader in fan technology. Below you can see the comparison airflow curves of ECFD EFP200 vs. EBM W1G200 fan assemblies at 1300rpm, 1550rpm, and 2100rpm. From these graphs, you can clearly see that our design meets and, in many cases, exceeds the performance of the W1G model. This was our goal from the start as we wanted to create the best performing fan pack assembly for energy-efficient refrigeration applications.

EFP200 vs. W1G200 - 1300rpm

EFP200 vs. W1G200 - 1550rpm

EFP200 vs. W1G200 - 2100rpm

Additional Features

Some of the additional features that make our product different than all the rest:

- With overall height being just over 3” this allows for a shorter installation depth than traditional shaded pole motors with steel fan rings and therefore helps to increase airflow rates in shallow applications.

- EFP axial fans can be supplied with U.S. Food and Drug Administration (FDA) compliant plastics qualifies for approval in areas involving incidental contact with food making it the perfect choice for supermarket open case vegetable display cases.

- Available in 172mm, 200mm, and 230mm diameters with a speed range between 300rpm to 2400rpm.

At the heart of the EFP axial fan is our ECY series EC motor which allows the EFP axial fan to operate as follows:

- 1 speed - single direction.

- 2 speed - simple wiring allowing the motor to be run in boost mode or trickle.

- Reverse on start which allows the motor to run in reverse for a pre‐programmed time on starting. This feature enables a more consistent and higher cooling capacity as it blows any particles of dust out of the condenser.

- Reverse on demand allows the customer to define the duration of reverse function. This is useful as it assists in eliminating icing when the evaporator is in defrost mode.

Further control function is available with our variable speed ECY-03 motor which is controlled via pulse width solution signal (PWM).

Protection is provided by both electronic and thermal devices and with IP65 rating as standard. This offers superior protection in the event of severe moisture applications.

The EFP axial fan has been independently approved by globally recognized 3rd party test houses and boasts ATEX approval allowing it to be used in the increasingly popular propane refrigerant applications without any spark issues if the refrigerant system malfunctions.

Our EFP axial fan (230VAC) has been tested by 3rd party approval agencies and satisfy the requirements of the European standard EN 60335‐2‐89 (Household appliance standard. Requirements for commercial refrigerating appliances).

Over the past 10 years, EC Fans and Drives have invested a significant amount of capital into developing new products for our customers to assist our entire industry in becoming more energy-efficient. This is our only goal, which is why we don’t have a broad product line as we want to be the best at EC fan technology in terms of performance, price, and delivery.

Product Compliance